Image Processor

Seamless Translation of Customer-Specific Design Layouts into Print Data

Heraeus Printed Electronics offers its unique Prexonics® Image Processor:

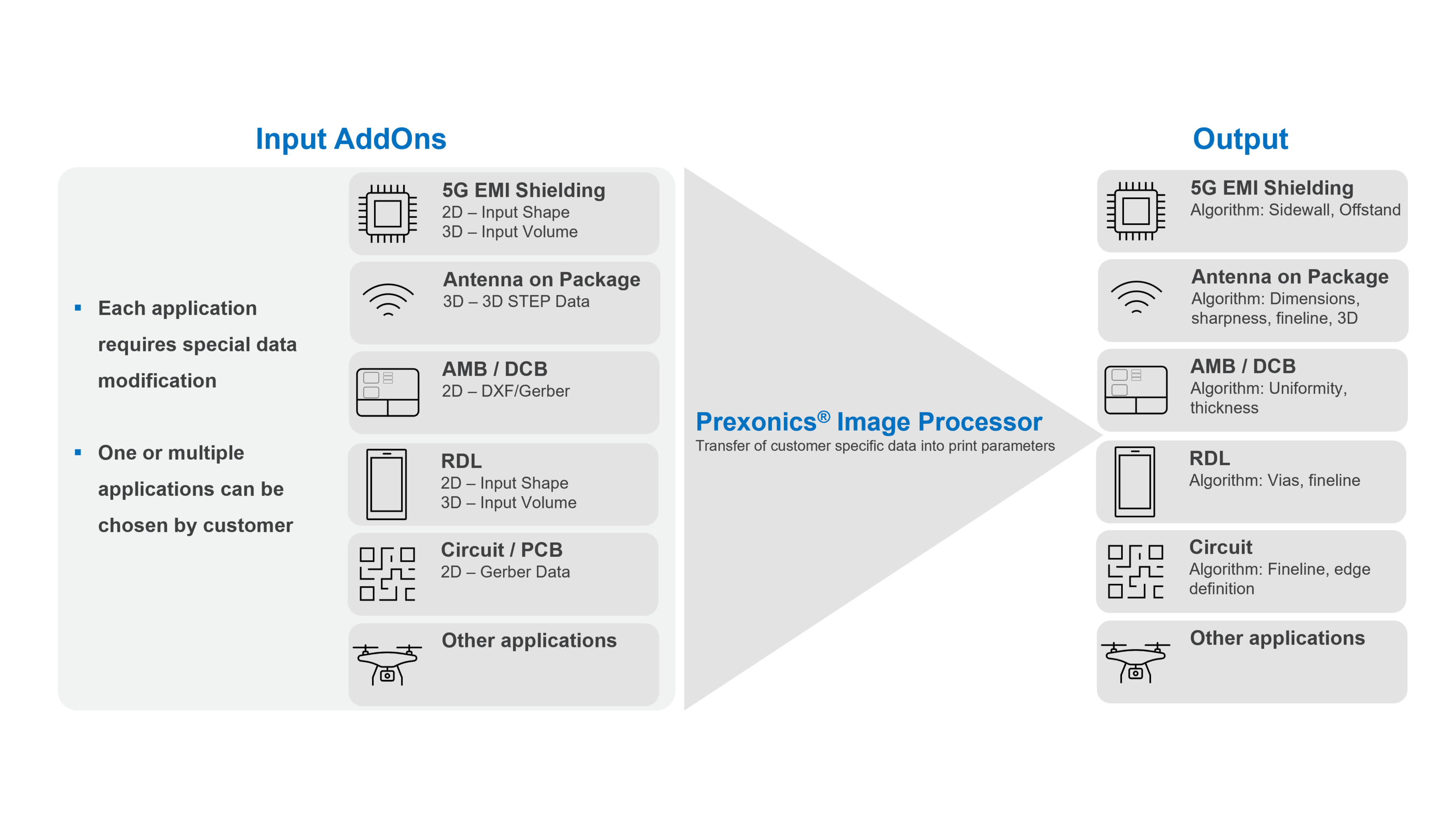

A software translating customer-specific design layouts into print data, opening the world of digital printing to selective metal coatings.

2D or 2.5D applications require great care, especially in data preparation and screening. Edge smoothing, data loss and density configuration are crucial for printed electronics. Data processing is tailored to the application and configurable. It covers the full data path from the input to the output data, fine-tuned for printhead operation and fulfills the standards of the semiconductor industry.

The Prexonics® Image Processor is equipped with standard print profiles and meta data tailored to substrate material, ink and print resolution. It also offers enhanced profiling tools to record product-specific parameters and take them into account in the automatic calculation of the print profile. Layer thickness and conductivity, as well as the coated feature size and edge sharpness can be tuned.

The Prexonics® Inkjet Printing Systems combine the print profile created by the Prexonics® Image Processor with the automated recognition of the shape, size, and location of each customer-specific substrate to be coated. This feature empowers users to create individualized print images with highest precision.

With the Prexonics® Image Processor, an extensive range of features is made available

► All kinds of free form design

► Coating thickness

► Conductivity

► Multiple reliability characteristics

► Precise control over line spaces & thickness

► Live monitoring and visualization of manufacturing conditions

during production